Units in service for many years, operating around the clock without standstill and maintenance stops, available anytime, require highest dependability for all components.

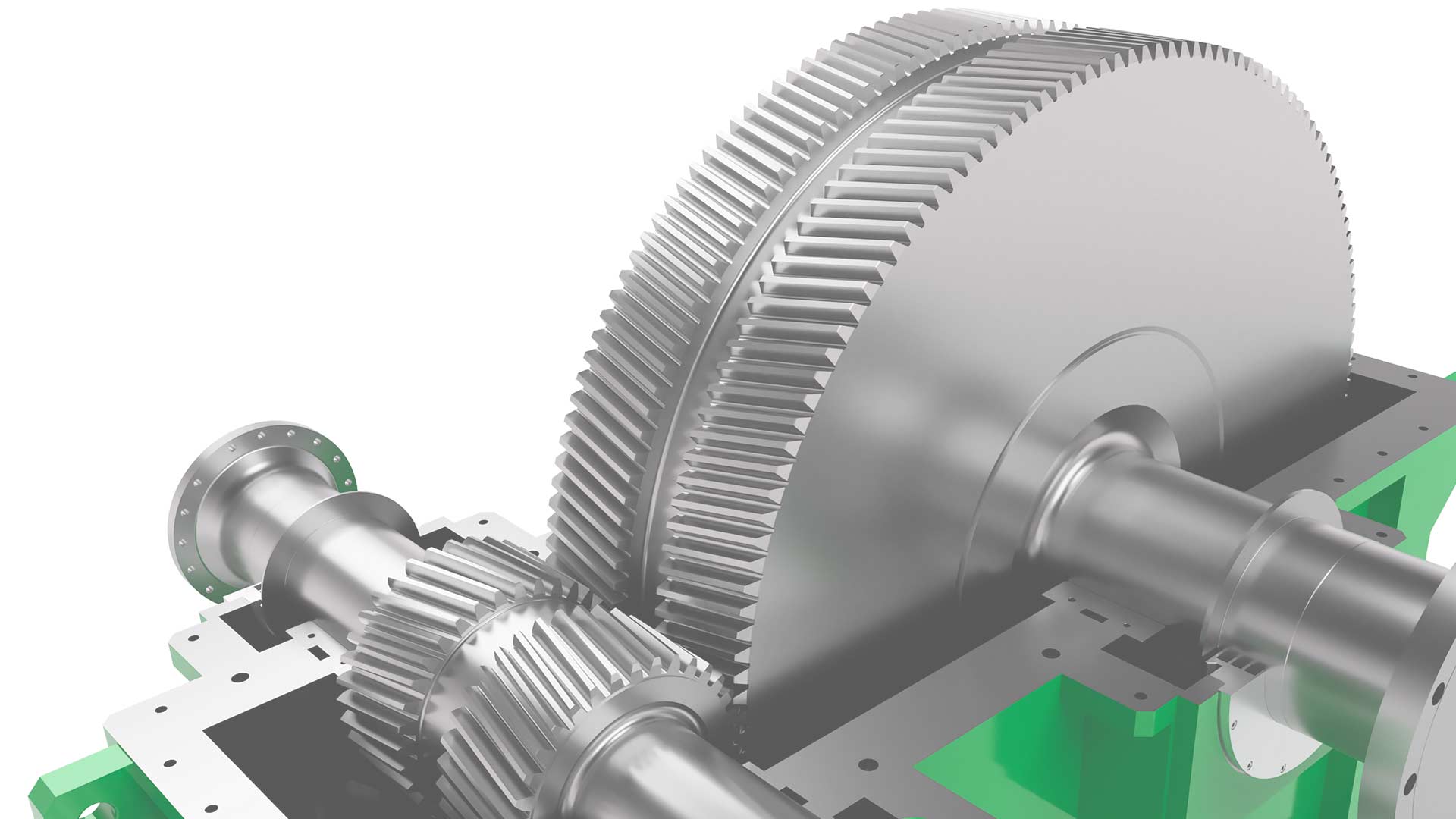

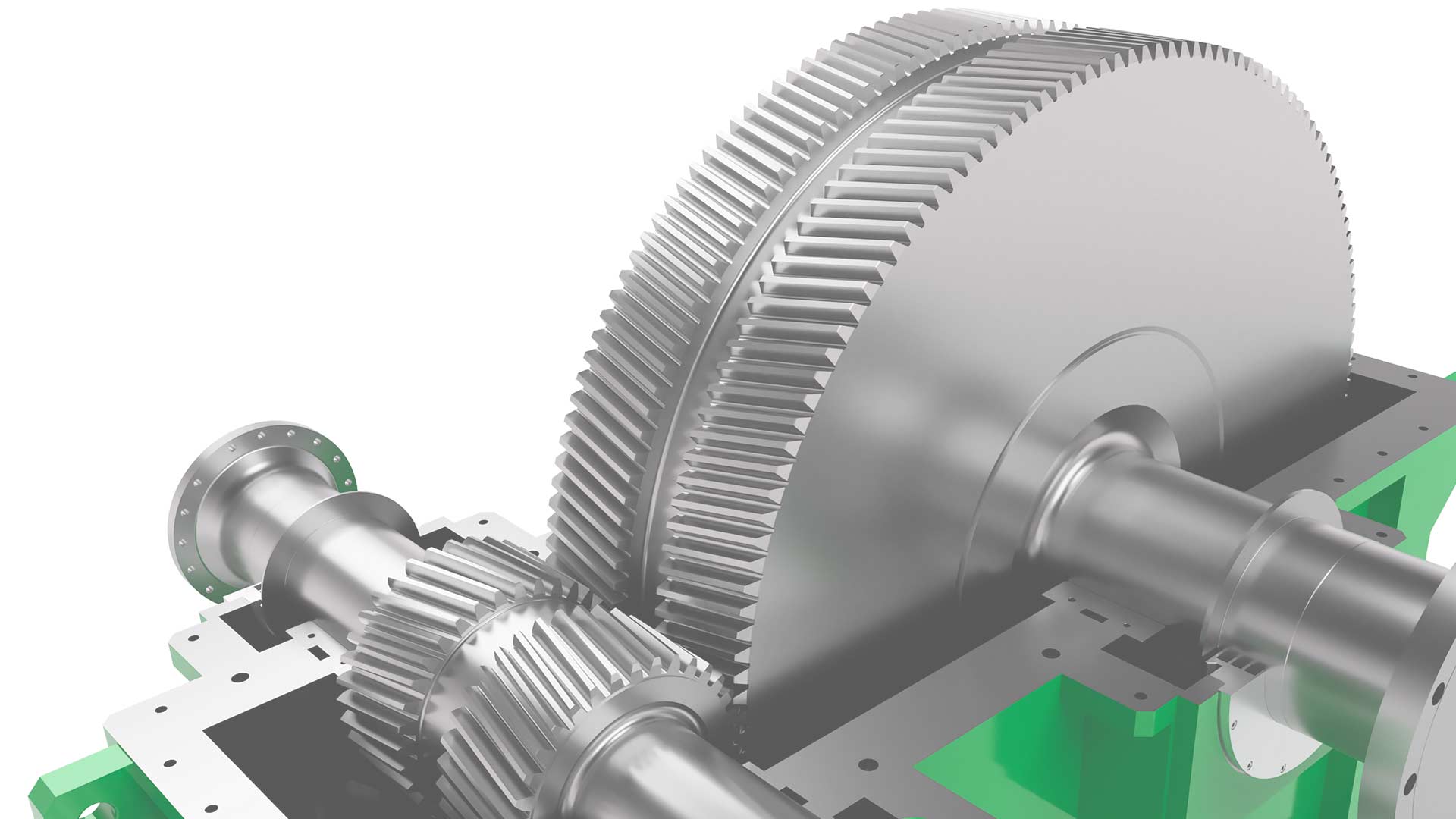

Therefore, our parallel shaft gears are built with hydrodynamic sleeve bearings and carburized gears, calculated for fatigue endurance and manufactured with highest precision. These measures minimize wear and extend the lifetime of the unit.

Compliance to international standards like API 613, longtime experience of our design and calculation experts as well as inhouse manufacturing and quality control guarantee highest quality and reliability of our gear boxes.

Power generation: Generators driven by industrial gas or steam turbines for power generation

Oil & gas: Compressors and pumps driven by electric motors or turbines for natural gas and crude oil production

(Petro-)Chemical: Compressors driven by electric motors or turbines for processing of various gases

Steel mills: Compressor and blower drives, energy recovery using expansion turbines

| Power | up to 60 MW |

| Speeds | up to 60.000 rpm |

| Efficiency | up to 99,2 % |

| Ratio | up to i = 10 (one state design) |

| Gears | Carburized single helical or double helical toothing |

| Bearings | Hydrodynamic sleeve bearings and tilting pad bearings |

| Casings | Fabricated casing with horizontal or vertical shaft offset |

| Designs | According ISO 6336, AGMA 6011 or API 613 |

My motivation:

“Provide the best results with state of the art technology and highest accuracy.”

Melanie Russler, 3D-measuring technology

29 years of turbogear experience